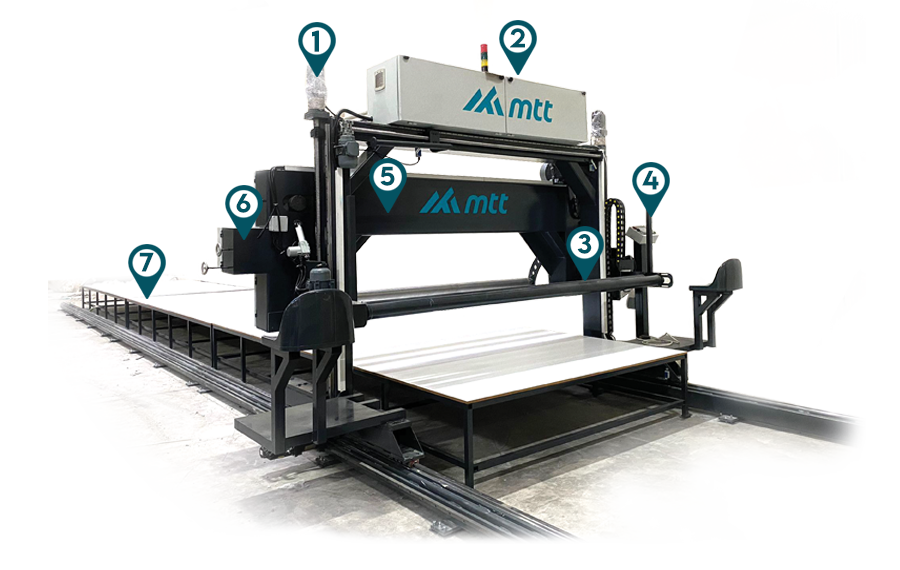

Independently working endless shafts and servo motors provide precise and quality cutting. It also provides easy calibration adjustment.

Interventions can be made for efficient cutting according to the dimensions of the products to be cut.

It enables both cutting and wrapping of the cut products in rolls. Since this section works in direct proportion to the bridge speed of the machine, error-free and regular winding takes place.

With its ergonomic and simple use, it facilitates the operator's monitoring and intervention of machine operation. Measurement and cutting programs are made.

Different cut sizes and changes in the angle of the sponges in DNS cause the difference in size between the blade and the table. Thanks to the angle and size optimization, this difference is automatically minimized without the need for operator intervention.

It provides independent sharpening of the lower and upper parts of the blade in optional proportion.

The length of the table is 14 meters suitable for block cutting and it is possible to combine in the coil winding section.